Dear Students,

Since many of you are online and working from home, we wanted to publish this small guide for making sophisticated models with simple means. In terms of working from home there are many model building techniques which are very suitable when you have no access to a professional shop facility.

01. The first thing you would need are the tools. When using board materials an X-Acto Knife (we recommend #2), a Cutting Mat, and a ruler are a great start to build many great models with. The ruler should be 24” minimum Imperial and Metric with a foam or cork back for stability and accuracy. The cutting mat should have a decent size something like 36×18” or 36×24” it is important that you store the cutting mat flat so it doesn’t bend (put it under your bed for example). Some glue or a hot glue gun complement your tools.

With this very simple setup, you should be able to build a variety of models using board materials like Foam-Core, Museum or Chip-Board. The strong X-Acto blade should also be able to cut basswood or veneer (by making multiple repeated cuts) if it is not too thick (X-Acto also makes a small hand-saw). You can also use basswood strips for more delicate models. You can also build forms for casting concrete or rockite (if you do so please follow the safety steps outlined in the online course you are enrolled in or contact the School of Architecture Model-Shop).

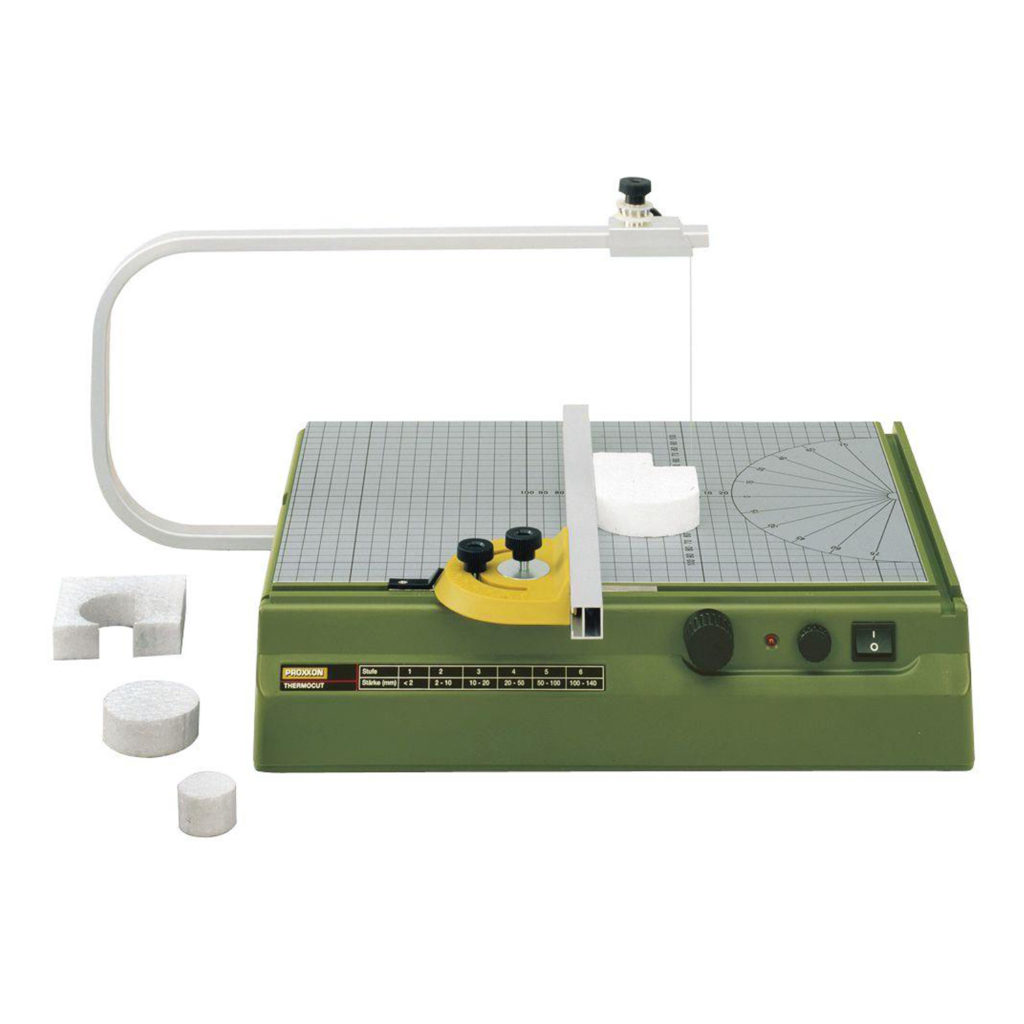

02. In the graduate department, we ask all incoming students to purchase a Hot-Wire Machine for cutting “extruded polystyrene” foam (not “extended polystyrene” – this is important). If you are using such a machine it is important to also buy the right Respirator as respiratory protection is required for certain operations (including but not limited to saw, router or hotwire cutting of extruded polystyrene foam (XPS or EXPS) that is Recommended for Hot Wire). So whenever handling (cutting or sanding) the foam, use an approved air-purifying respirator with organic vapor cartridge and a particulate pre-filter. For gluing foam, we recommend Uhu-Por which is by far the best glue for bonding the foam, wood glue or any water based glue which doesn’t resolve the foam would work too. When working with foam, please follow the safety steps outlined in the online course you are enrolled in or contact the School of Architecture Model-Shop for instructions and safety measures.

You can order simple to use and budget conscious Hot-Wire Foam Cutting Machines for around $100. We recommend the Proxxon Thermocut as a minimum it provides a decent accuracy. This machine is suitable for all courses you encounter in the graduate program.

Another machine which is much more sturdy and accurate is the Styrocut from a small German cottage manufacturer, which you should only consider if you really like working with foam as this machine comes at a much higher price point.

This setup is like having a small model shop of your own. The machine requires a little practice to find the optimum speed between pushing the foam and the temperature of the wire. Once you mastered this, the possibilities are endless. Foam models are widely used in architectural offices and the material can be found in models from early concepts up until sophisticated presentation models.

Please insure that you obey all safety measures lined out by the manufacturers of the described materials and tools in this blog-post. The School of Architecture and the Academy of Art University can NOT be hold responsible to any damage or injury.

Please also regard our other model building resource blog posts here and here.